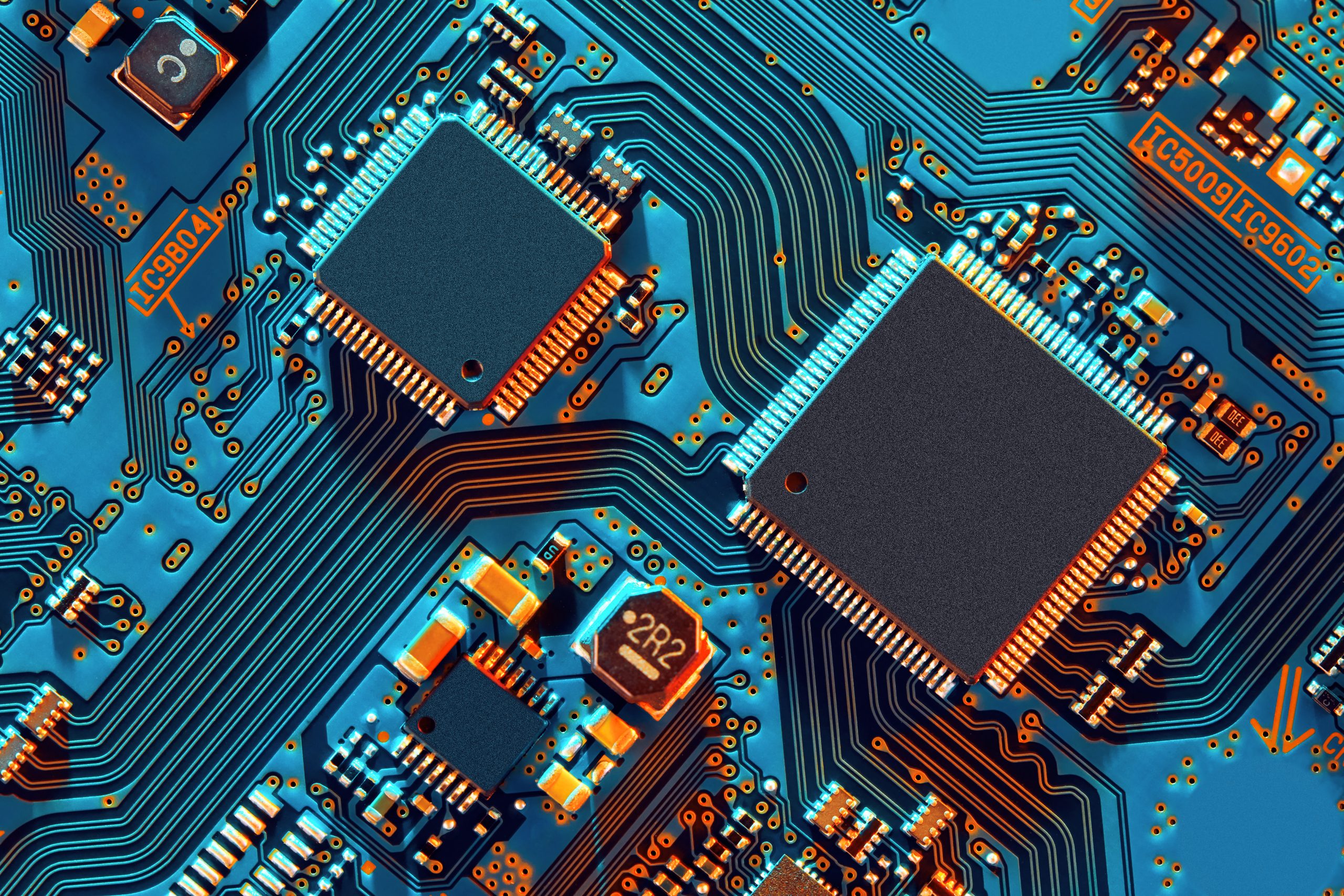

We specialize on printed circuit board assembly.

We are a contract-based electronic assembly and turnkey manufacturer that provide excellent quality products for our valuable customers around the world. Our specializations range from surface mount and through-hole components on double-sided printed circuit board to an entire assembly.

Pick and Place

With low overhead and efficient processes, we can provide to our customers with low cost production solutions. We can accommodate small production runs, urgent order and quick turnarounds.

Reflow

We design and layout printed circuit board to be sent for fabrication.

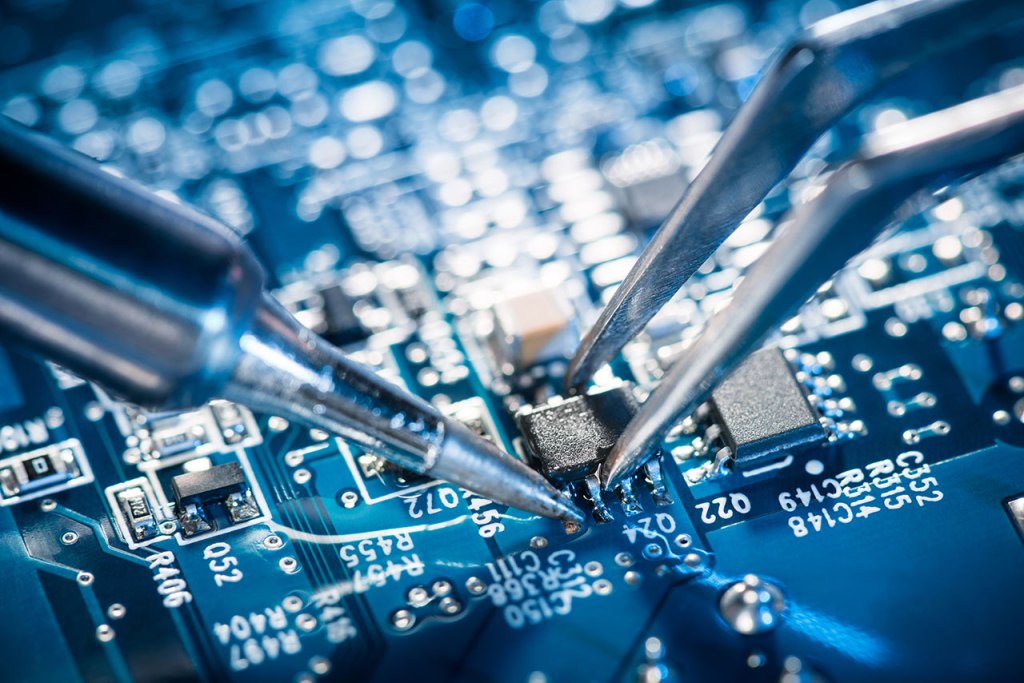

Hand Assembly

We will work with you to develop your prototypes, complex designs, cables, wiring harnesses, and any rework assemblies

About Us

M-Tronic was established in 2001 by current owner Vang Moua. Having 20 years+ experience, Moua specializes in the mixed technology of contract electronic assemblies, and turnkey contracting manufacture. He has strived to produce the best quality products at a low cost. M-Tronic is 100% lead free Electronics Contract Manufacture. M-Tronic also designs and layout printed circuit board and create Gerber data ready for PCB fabrication accordingly to our customer’s specification

Our Mission

To achieve and utilize continuous process improvement strategies to ensure the highest quality products and services to meet our customers expectations. To develop customer relationships, which provide services tailored to specific customer needs. To provide employees with ongoing training to enhance knowledge and skills, develop problem solving and decision-making abilities, and offer opportunities for advancement

Quality

We are committed to maintaining and continuously improving the quality of our electronic assemblies and services to meet our customers’ expectations. We concentrate on ISO guideline, and our goal is to surpass the standards set by our customers. By coordinating your efforts with our production facility, we can expedite your project through every stage while guaranteeing a quality product. We believe that quality is the most important attribute for building your products.

- IPC-A-610C Class 2 and 3 Standards for Acceptance.

- 100% Testing with procedures and fixtures.

- ESD controlled and tested.

- Continual Employee Training for ESD.

- Statistical Process Control for improvement.

- Continuous improvement of Top Quality Management.

Example Products

We have assembled a variety of products including security system, robotic equipments controller, audio/video system, LCD display driver, animal pulse and blood pressure monitor, surgical monitor for the Vet-clinic, and ultrahigh frequency circuit board for satellite communication that sold to the US government.

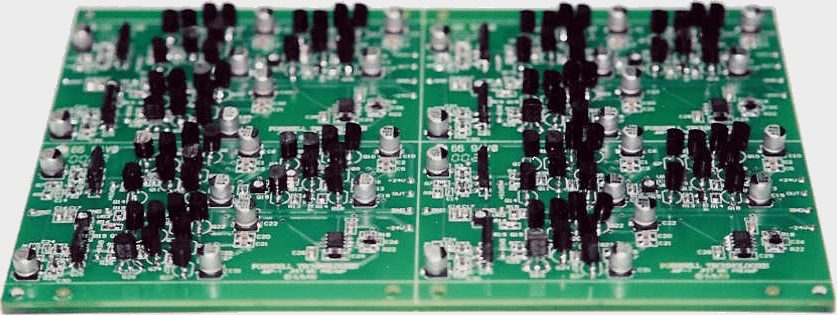

Circuit board with Melf components, SMT component size 402 to C-case electrolytic capacitor, and components are installed on both side of the board and mixed with standard thru-hole on the top side.

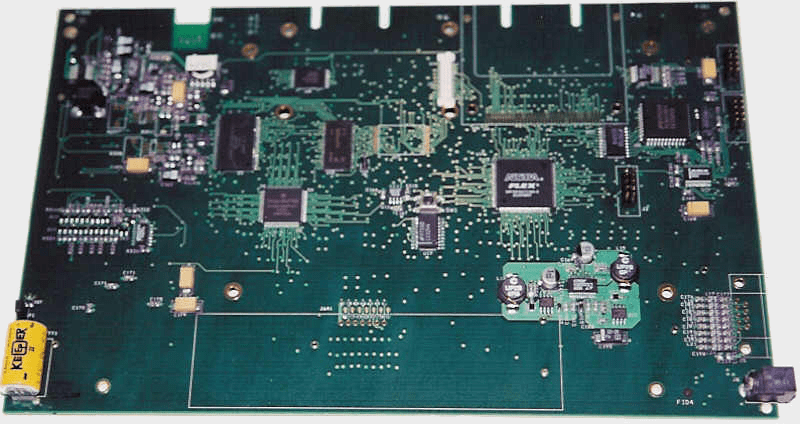

Multi-layer board with component size 603 and up, IC TQFP @ 12 mil. pitch, and components are installed on both sides.

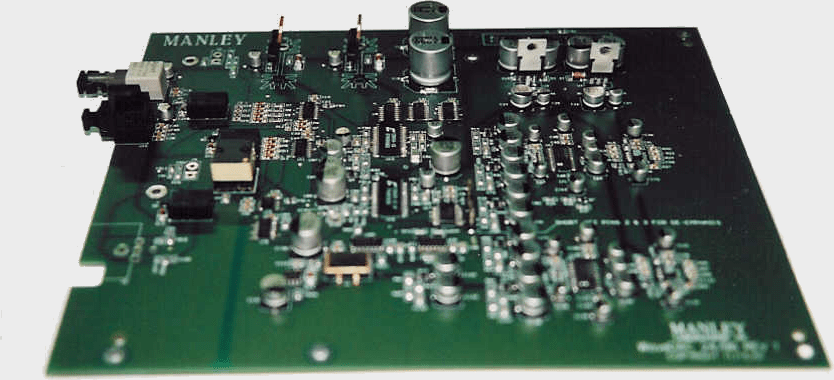

Multi-layer board with SMT size 805 and up to high current power components and mixed with several different types of connector.

Our Services

At M-Tronic, we have the capability to work with single sided, double sided and multi-layer circuit boards. PCB size ranges from 1/2 x 1 inch up to 20 inches width, and chip component sizes range from 402 and up. All applications can be mix with standard through hole component and install on both side of the circuit board. In addition to our PCB capabilities, we also work with cables and wiring harnesses assemblies that involves wires stripping, tinning, crimping and soldering.

We take pride in our competitive low cost and high quality products. We have provided the following services to our customers and have received excellent feedback for our outstanding services, quality products, best prices and meeting customer’s requirement.

- PCB design and layout to meet customer’s specifications

- Schematic Design, Library development

- Engineering documentation

- Prototype builds

- Surface mount PCB assembly. “Fine Pitch” Capabilities

- Thru-hole printed circuit board assembly

- Low to medium volume production

- Mechanical, electro-mechanical assembly, and packaging

- Complete functional testing on the product we built with our customer’s test equipment

- Turnkey contracting manufacture

- Rework printed circuit board assemblies to meet customer’s requirement.

- (Installation or removal: BGA, CSP, µBGA, TQFP, QFP, PLCC, SOIC, TSOP, SOL, SOT, Chips and thru-hole components)

- Cables and wiring harnesses assemblies

- Lead-free production capabilities

Immediately following a client order, we procure and inspect all require components. We methodize drawings and color coded SMT components for automate pick and place and conventional thru-hole for manual placement. Component placement, reflowing, soldering, cleaning and assemblies are performed in our facility to complete the manufacturing cycle. We performed quality control, inspection and testing at appropriate steps during the manufacturing process while utilizing comprehensive Statistical Process Control (SPC). We performed 1% AQL (audit) at a final step prior to packaging. Completed assemblies are marked date-coded and anti-static packaged for shipment